Like plastic rubber is a polymer which is a chain of repeating units called monomers in rubber the monomer is a carbon compound called isoprene that has two carbon carbon double bonds.

Rubber band chemical formula.

The chemical compatibility of rubber is extremely important as the rubber can degrade rapidly if the rubber material is not compatible with the environment or media that it comes into contact with.

1 satisfactory 2 fair 3 doubtful 4 unsatisfactory x insufficient data.

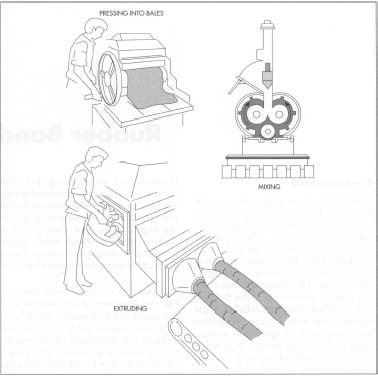

All compounds require the addition of other materials to create a finished product.

What makes rubber so elastic.

Starting point rubber compounding formulations.

The latex fluid that seeps from rubber trees has many isoprene molecules.

Phr for their formula.

A rubber band also known as an elastic band gum band or lacky band is a loop of rubber usually ring shaped and commonly used to hold multiple objects together the rubber band was patented in england on march 17 1845 by stephen perry.

Clay common filler in rubber band compounds.

These are starting point rubber compounding formulations for providing guide lines only and should be confirmed by laboratory trials.

These changes can have a dramatic effect on the service life and properties of the elastomers and can only be prevented or slowed down by the addition of uv stabilizers antiozonates and antioxidants.

It is expected that modifications may be necessary to produce satisfactory commercial products.

Compound the formula for a particular rubber band compound.

Thermal oxidative degradation of rubber most elastomers will undergo significant changes over time when exposed to heat light or oxygen ozone.

Natural rubber also called india rubber latex amazonian rubber caucho or caoutchouc as initially produced consists of polymers of the organic compound isoprene with minor impurities of other organic compounds plus water thailand and indonesia are two of the leading rubber producers.

There is no such thing as a 100 pure rubber band.

With over 80 years of experience and product development alliance has designed specific compounds with varying stretch performance to create.

Types of polyisoprene that are used as natural rubbers are classified as elastomers.

Most rubber bands are manufactured out of natural rubber or especially at larger sizes elastomer and are sold in a variety of sizes.

In any molded rubber product the three major influences of part quality that we control are the mold the process and the rubber formulation.

In simple words we can say that they are made by loosely joining the monomers of isoprene c 5 h 8 in the form of a long tangled chain.